The U.S. Department of Energy is funding two national laboratories to initiate efforts toward development of an open platform “digital twin” technology. The first task of the laboratories is to gather input from industry. Responses to the request for information are due March 17, 2021.

Gathering Industry Feedback – Why It Matters

Specifically, funds are being used by Oak Ridge National Laboratory in Tennessee and Pacific Northwest National Laboratory in Washington to develop a roadmap for a long-term research effort for a “Digital Twin for Hydropower Systems – Open Platform Framework.”

DOE has directed the labs to:

- Elicit from hydropower stakeholders the information needed to appropriately scope the research effort

- Use the responses to document and publish the value proposition and appropriate scope for the project.

- Draft, publish, and refine a specification and roadmap for the research effort.

In a National Hydropower Association-hosted virtual seminar held February 2 on the topic, DOE emphasized the importance of industry engagement in the development of digital twin technology for use in hydropower systems.

“It’s essential that the specifications and roadmap for the project fully address the industry input and value propositions,” says Mark Christian, Technology Manager, Fleet Modernization, Maintenance and Cybersecurity, for DOE’s Water Power Technologies Office. “We need industry input to create a tool that is useful and usable.”

Christian says it should take no more than 45 minutes to answer the 30 questions in the request for information.

Understanding the Digital Twin Technology

A “digital twin” is simply a virtual representation of a real-world system, according to researchers at Oak Ridge National Laboratory in Tennessee and Pacific Northwest National Laboratory in Washington. As an example, Honeywell is using a digital twin to improve it’s oil and gas production energy performance. The twin tool is also used in a variety of other applications and is even being used to help rebuild Notre Dame Cathedral in Paris.

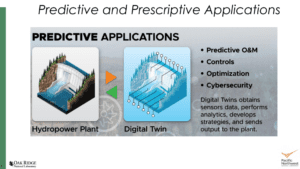

This digital twin technology can be used in a multitude of ways in the hydropower industry, toward meeting goals of enhancing efficiency and reducing maintenance costs and outages.

“We see a number of applications for a digital twin tool in addition to day-to-day uses for improving maintenance timing and reducing system downtime,” says Christian. “For example, the tool could be used in cybersecurity applications to detect network intrusion and to enable AI-based assessments. And, the tool could be used in investment and market planning to conduct ‘what if’ analyses of market scenarios and impacts on equipment and components.”

Digital Twins can be used not only to find and fix problems for a specific hydro plant, but they can also be used to proactively identify similar problems at other plants and prescribe fixes well in advance of the problem actually occurring, says Oak Ridge and Pacific Northwest lab investigators.

Real-World Application

Chelan County Public Utility District, an owner of hydroelectric projects in Washington State and a member of the National Hydropower Association, sees lots of benefits in the use of digital twins. “We define a digital twin – or a digital performance twin – as a mathematical model that represents a physical system,” says Kirk Hudson, managing director of generation and transmission for Chelan County PUD. “With this performance twin, we can simulate in a digital world the changes we are considering in the physical world – without breaking things.”

Like many hydro project owners, Chelan County PUD is looking to use data to drive and improve decision making and to become more skilled at predicting future performance. A digital performance twin can aid in this pursuit.

Chelan County PUD used the concept to build a stator temperature predictive model. The resulting temperature prediction tool shows that a current increase of 500A will reduce the remaining life of the unit by 7 percent.

Hudson says challenges faced in development of the performance twin was having access to enough data to build a robust tool and having the skills and expertise to build and calibrate the twin to account for different variations in the physical system/equipment.

As a result of its work, Hudson says Chelan County PUD has identified the need for new types of sensors to feed the data collection effort, along with a need to understand the tools and processes that are available to customize the models for specific parameters.

As the public utilty continues to consider use of digital twin technology, Hudson says the key is to ensure the technology is accurate enough for use in decision making, and that the tool fits the culture of the organization and adds tangible benefit.

What’s Next

The vision of the DOE-funded Digital Twins for Hydropower Systems project is to develop an open platform tool with open system architecture, open sourcing and an open data integration platform. The goals are for the tool to be affordable to own, simple to operate, and flexible and adaptable to specific user’s needs, says DOE’s WPTO.

“We like to think of the effort as a strategic initiative that can serve as an ‘open playground’ for research and innovation for the hydropower industry, with involvement from project owners, equipment manufacturers, national labs, and academia,” Christian says.