*Sponsored Content

Small scale hydropower is environmentally and socially responsible. Scalable installations for any landscape or location provide a short return on investment with a long asset life. Quick to develop and with minor impact on the environment, these installations can make a significant contribution in the fight against climate change.

This is particularly true in rural or isolated areas with less stable or limited power supply grids. The integration of new or existing small hydro with other local generation projects provides increased power reliability and stability to those industries and communities, who often face increasing demand using aging or outdated technology.

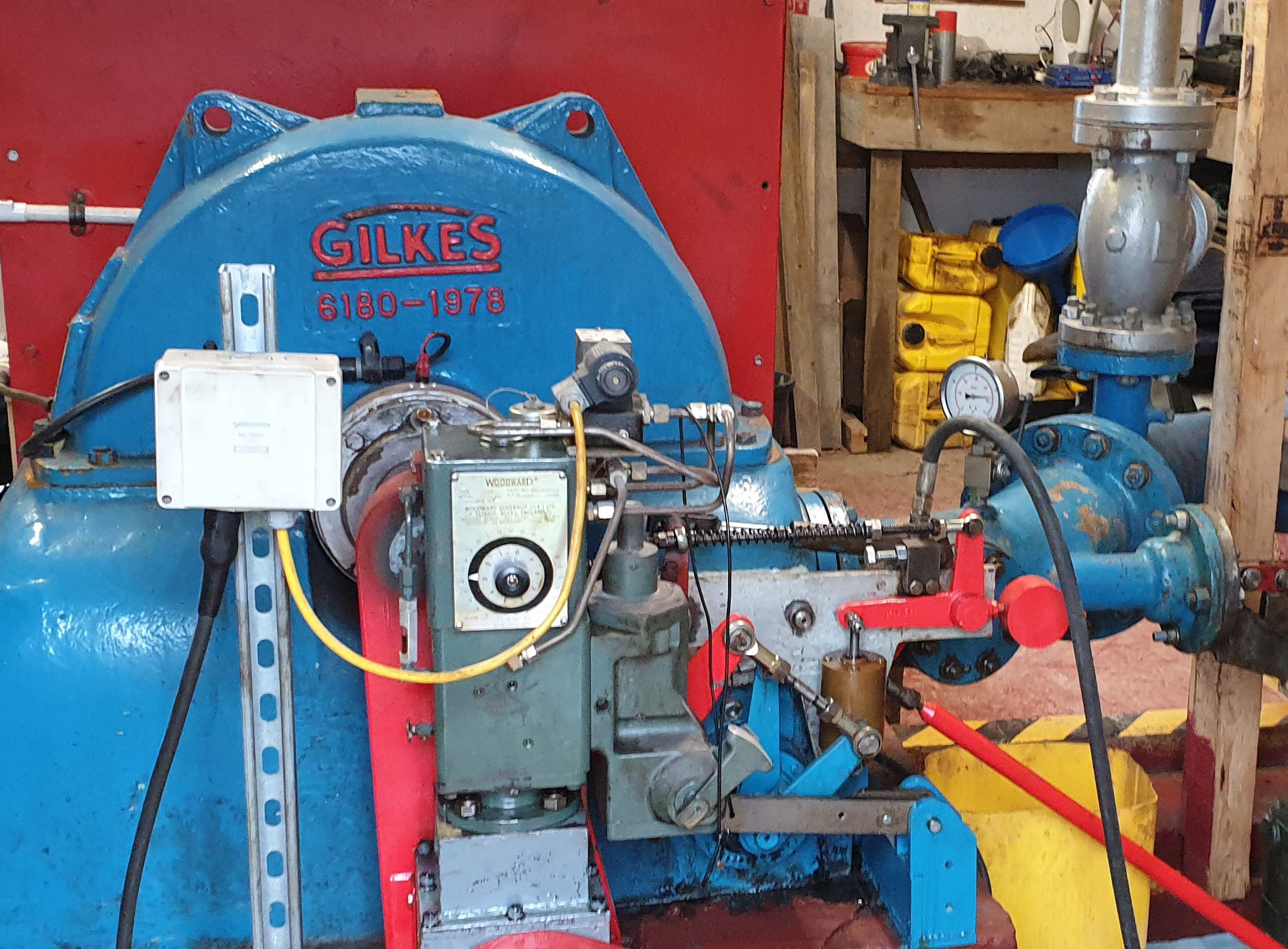

Globally, there is an increasing need to modernize and optimize aging installations to maintain their lifespan and increase generation. With a refence list dating back 170 years, Gilkes has a great deal of experience in these projects, ranging from single-part replacements or upgrades to the rehabilitations of whole hydro installations back to their optimum working levels.

ADVANTAGES OF MODERNISING A HYDRO PLANT

Some advantages of modernizing a hydro plant are:

- Improved Plant Productivity

- Optimized Energy Generation

- Increased Reliability

- Lower Operational & Maintenance Costs

- Extended Lifetime

- Plant Safety Improvements

- Meeting Compliance Regulations

The following case studies demonstrate small scale power generation in remote locations, and the need to upgrade and maintain these hydro plants to secure future energy generation and long-term operation of the plant.

Knoydart Hydro, Scotland

The Knoydart Community, Scotland.

Knoydart is a peninsula in the Lochaber district on the West coast of the Scottish Highlands. Situated between Loch Nevis and Loch Hourn, the peninsula comprises approximately 55,000 acres, which today is divided up amongst several landowners, with the largest area managed by the Knoydart Foundation.

Knoydart is cut off from the UK mainland road network, meaning access can only be made either by boat or by foot and is not connected to the National Grid, generating all its own electricity. Other than some small run-of-burn micro-schemes in outlying hamlets, by far the main producer and distributer of electricity on Knoydart is Knoydart Renewables Ltd hydro scheme. The Hydro scheme is managed by the Knoydart foundation, which is a local community owned & managed foundation.

The Knoydart powerhouse.

Increased Generation

The single jet, 280kW Pelton turbine, with a cast iron case was originally installed by Gilkes in 1977. In 2000 Local investment allowed the foundation to conduct work to increase the plants’ energy generation, with an aim secure Knoydart’s energy future. At the time, the turbine was only generating 50 or 60kW of power, intermittently with frequent outages. Replacement of the original penstock with an overground penstock and removal of restriction flow at the dam increased the output to 235kW.

Knoydart’s original Gilkes’ turbine.

In 2020, Gilkes were approached to conduct the next phase of modernization work to further modernize the mechanical & electrical equipment and improve the frequency stability. The existing machine was also suffering from breakdowns and bearing issues. As with most modernization projects there was an initial site visit conducted by Gilkes engineers to carry out a site survey and condition assessment. The resulting scope of work was:

- Mechanical refurbishment of the turbine.

- Re-governing of the system including new deflector control cylinder, hydraulic control module and digital speed governor.

- New generator.

- New control and switchgear panel with remote monitoring and future ability to run in parallel with a diesel generator.

- New DC battery panel to provide easy black start capability.

The new system also has an HMI that can be remotely accessed for diagnostics when the customer connects to internet, allowing less frequent visits. It also allows remote access for Gilkes engineers, providing turbine data for more informed fault diagnostics and condition monitoring. The work has resulted in improved reliability and serviceability into the future.

The commissioning of a refurbished turbine.

In addition to the Gilkes scope of work, further civils work was carried out by the foundation, with a new underground penstock to replace the above ground penstock which was susceptible to degradation from the elements. The new penstock of larger diameter maximises the available head for the turbine, with the option to add a second turbine in the future.

Energy Security

As a result of the continuous upgrade work conducted on Knoydart Hydro scheme, the machine is now able to achieve its maximum capacity of 280kW, with the added ability to synchronize with the new back up diesel generator during times of maintenance on the hydro equipment.

The hydro generates power according to community demand. While demand is currently relatively small, the hydro is not generating to its full potential, but in the future, with new settlements, and a new brewery, the load demand will increase, and the community are well prepared to secure enough renewable energy to manage that demand.

The intake at Knoydart.

Knoydart’s energy security project guarantees a clean, affordable, dependable, entirely green, and renewable supply of electricity to drive the economic regeneration of Knoydart. Adding new domestic and business connections to the network will ensure sufficient income is generated to support the long-term operations of the system.

Dimbolil Hydro, Kericho, Kenya

The Dimbolil powerhouse in Kenya.

Hydropower on Kericho Tea Estates

Finlays Tea Estates is in the highlands of Kericho, Kenya and covers 10,300 hectares, containing four tea factories. The Kericho estate is a thriving community of thousands of employees and their families, who live work and study there. There are 14 primary schools, 50 nursery schools and 2 secondary schools on the estate.

Hydropower has been used for power on the tea estate as far back as 1931 when Gilkes supplied the first turbines to the Saosa Hydro plant. Since then, 10 Gilkes turbines have been supplied to 5 separate hydro plants on the estate.

Dimbolil Machines

The Dimbolil Hydro plant was built in the 1940’s and houses 2 Turgo turbines, 1 of which is an original Gilkes 21” twin jet Turgo turbine which is still in use. The second machine was installed at a later date and when Gilkes were approached to carry out an inspection of this machine in 2019 it was not generating to its full potential. The aim for Finlays was to get this machine running to its full potential and up to modern standards.

Refurbishment/Upgrade

A full inspection by Gilkes engineers was initially conducted to establish the scope of work required. Refurbishment of the second turbine originally started out about 50% of the installed equipment, but as the project developed and further corrosion was uncovered the scope of work increased to almost all the equipment.

The final scope of work carried out included Gilkes designed supply of a new MIV, branchpipe, spear assembly, deflector assembly, full rotating assembly (including runner, shaft and bearings), generator, control panel , HCM.

The commissioning work at Dimbolil.

Operation

Prior to refurbishment the Dimbolil scheme required an operator to check the intake daily to manage the flow. This is now no longer necessary, after the installation of a head level sensor. Although they still have a skilled operator on site, the flow can be managed via a screen in the powerhouse rather than a walk up to the intake. This semi-manual control option ensures local employment is still needed. On completion of the refurbishment work, our engineers provided training for the local operators.

Operators being trained on equipment in Dimbolil.

Challenges of Modernization Projects

The Finlay’s Tea estate is very well run and therefore did not pose any logistical challenges for our engineering team. The biggest challenge when undertaking refurbishment and modernization of old equipment is access to original drawings. While Gilkes have an extensive archive of drawings going as far back as 1900, on this occasion they were not available, meaning the engineers had to rely on accurate measurements taken during the inspection stage of the project.

Summary

Following refurbishment, the Dimbolil machine has seen a significant Increase in power from the original design (100kW) to 240kW, surpassing the customers’ expectations.

All 5 hydro plants on the Kericho Estate are connected to the central mini grid. The power generated is all consumed on the estate, helping to power the factories, villages, schools, and other services. 30-40% of the electricity comes from their hydro and biogas.

The new HCM installed in Dimbolil.