Sponsored Content

Energy recovery in the context of hydropower is the extraction of the potential energy of flowing water from a pressurized water source, usually already in existence for pre-prescribed purposes.

Pre-prescribed purposes include:

- Transfer of water from one reservoir, tank, holding source, to another

- Conveyance/transfer for municipal drinking water delivery

- Conveyance/transfer of raw water to water treatment facilities

- Waste water treatment applications

The above types of conveyance or transfer occur typically under a gravity fed scenario through a network of large and medium diameter pipes, or aqueducts, but can sometimes be pumped applications. In any case, pressure builds from the higher elevation to its lower point of distribution and needs to be reduced prior to entering either a water treatment plant or a municipal distribution system.

In the majority of situations, the pressure at the point on treatment or distribution is reduced by the means of a pressure reducing valve or PRV. These valves destroy the potential energy of the water that has built up in the pipelines and reduces it to an acceptable pressure level for commercial and household distribution. These PRV’s consume energy in terms of the electrical power required to operate it.

ADVANTAGES OF ENERGY RECOVERY USING HYDROPOWER

- Energy Generation from an Existing Process

- Reduces Environmental Impact

- Turbine as a Flow Control Device

- Replaces Pressure Reducing Valve Function

- High Efficiency and Reliability

Photograph of Gilkes’ Pelton turbine.

Gilkes offers solutions whereby the potential energy that was once destroyed can be utilized for power production.

Gilkes has a range of turbines that can be optimized to a specific site to harness the potential energy of the water and turn it into electricity, utilizing either a reaction or impulse style of turbine. Where downstream pressure is required, or a turbine is fitted within a pressurized system, a Francis (reaction) turbine is the preferred choice. If the turbine can discharge to atmosphere, then a Gilkes Turgo or Pelton turbine can be installed. The Gilkes Turgo is ideally suited to and is often installed at the head of a water treatment facility where it can be utilized to control flow through the facility as well as generate power at the same time.

The electrical power that is produced by our turbines can be used in a number of different ways;

- The electricity can be used to power a water treatment/wastewater treatment facility to offset their annual energy consumption in a ‘behind the meter’ application

- The electricity can be sold directly in the grid with the means of a power purchase agreement

- If more power is produced than can be consumed, a combination of behind the meter and export to the grid can be achieved

In all scenarios, water delivery is paramount and energy recovery a secondary function. To ensure the safety of the treatment plant or municipal headworks, the turbine will almost always be placed in parallel with a PRV to ensure that if either is offline for any reason, water can still be conveyed as needed for processing or delivery to consumers.

BRYN COWLYD WTW ENERGY RECOVERY PROJECT

The Bryn Cowlyd Energy Recovery Project is an example of an energy recovery turbine being used for flow control at the same time as generating renewable energy.

The Water Treatment Works in the county of Conwy in Wales is fed from Llyn Cowlyd, which is the deepest lake in north Wales. The WTW was commissioned in 2019 and is Welsh Waters’ flagship works.

Gilkes were approached by Skanska Construction for the detailed design, manufacture, testing and installation, commissioning, and training of an energy recovery turbine suitable for flow control at the inlet to the works and to generate renewable energy, which would contribute to the on site load required to operate the water treatment works.

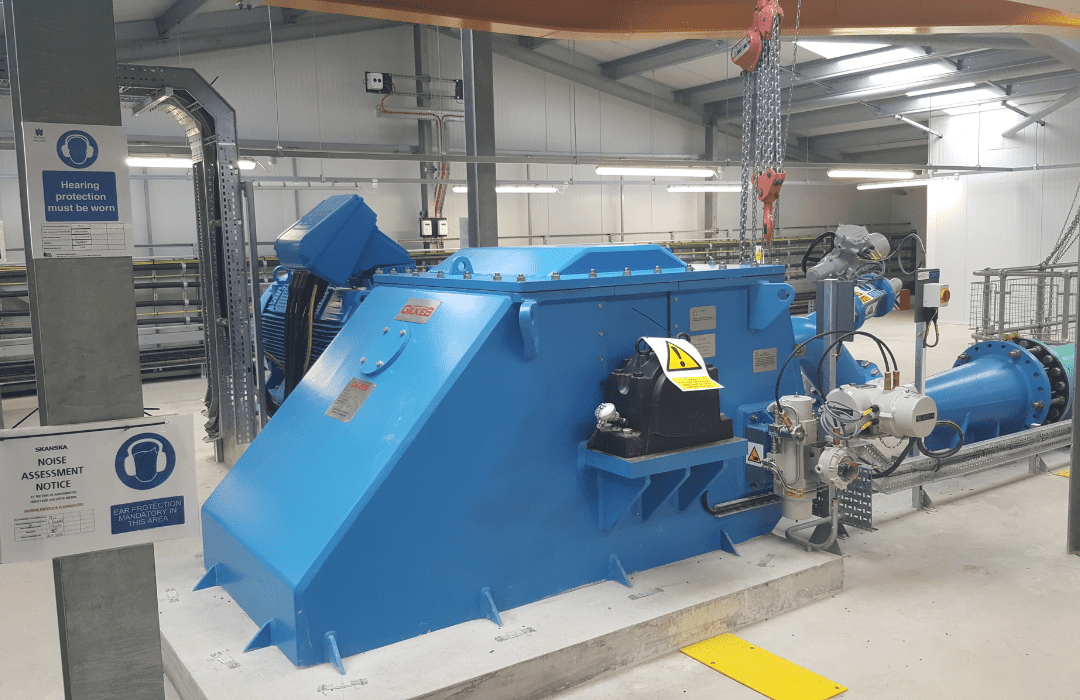

Photograph of Bryn Cowlyd Water Treatment Works

Welsh Water, Skanska, and Gilkes worked together to determine the most suitable turbine and generator. With a net head close to 200m and a flow rate of around 323l/sec the hydrology was suited a Pelton turbine. After monitoring the expected variations, a 750mm single jet Pelton turbine was selected for efficiency and maximum annual energy production.

It was an interesting project for Gilkes, as this was the first water treatment works where the entire project was done under BIM (Building Information Management), meaning a full 3D walk though of the treatment stages, energy recovery turbine, and final treatment was available during the design stage and for hazard awareness.

Although the turbine could have been offered in a compact, streamline format, the machine was offered in a more heavily built design to ensure that noise from the turbine was kept to a minimum.

Gilkes has supplied equipment for energy recovery around the world, including North America, Africa, and Australia. Further case studies can be viewed here.

Gilkes Turgo Turbine at Hurricane Hydro in Utah.