We at the National Hydropower Association (NHA) understand how difficult it can be to step away from work to attend an industry event. Yet, we encourage you to think a bit “outside the box.” Instead of looking at attending an event as a time suck, think of it as an investment in organizational and professional growth.

To understand why asset owners find value in attending industry events, NHA interviewed Jim Thrasher, business development manager, Thompson.

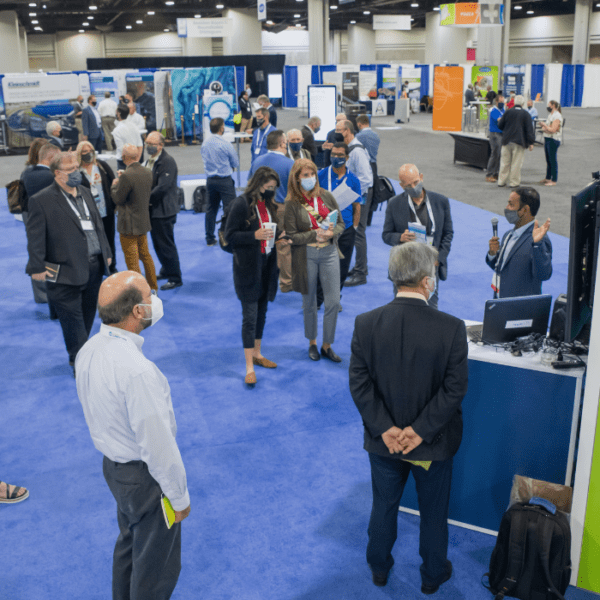

Thrasher says whether you’re an executive at a major utility or a small business operating one or two generating facilities, the “by the industry, for the industry” Clean Currents Conference + Tradeshow occurring the week of October 17 in Sacramento, California, will deliver answers, expertise, and connections; he added, “Take a week off, go to Clean Currents, do the research there, and you won’t be disappointed.”

POWERHOUSE: When working for an asset owner, what made you interested in attending national conferences?

Jim Thrasher: I joined [American Electric Power] AEP while it had a very strong, experienced hydro staff. The hydro plants were in good condition both from a civil perspective and a mechanical perspective. We were focused on improving production and optimizing our profit margin.

But, then, things changed.

Many of our key people retired and were not replaced. Downsizing became the new movement in investor-owned utilities.

Coinciding with the loss of good, experienced people, we started seeing problems with our equipment that we’d never experienced before. I realized much of our equipment was reaching the end of its life cycle, and this was a new problem for AEP.

There was no one to turn to within AEP for answers or help. After all, hydro was only 4% of the generating portfolio for AEP.

I started going to industry events for answers, and it paid off.

POWERHOUSE: Can you provide some examples of things you learned at these events and how they helped or inform your work?

Jim Thrasher: Sure. I have a couple of examples I’d like to share.

The first one that comes to mind is the information and advice I received about discharge ring replacements. AEP had “patched” discharge rings for years. They were practically beyond repair on many of the Kaplan units, so I attended a session on discharge ring replacements. The presentations showed the condition of the original discharge ring, the removal process, the process to install new stainless steel discharge rings, and the presenters shared the cost of their work.

Beyond that, the presenters also were willing to engage with me after the session, which allowed me to grow my network and gave me access to experts I could approach with technical questions. The information and help I received resulted in AEP replacing nine discharge rings on Kaplan units that had diameters of 177 inches.

Another example I can think of has to do with the struggles AEP was having with trash problems at its project on the Ohio River. We had not found a trash rake that could handle the volume and size of debris in the Ohio River. We gave up on rakes and used a crane to clam shell the debris from the intakes. This required taking the unit offline, removing the debris, placing it in tractor trailers, and hauling it to a landfill. This was practically a daily routine.

I attended a session on removing debris from large rivers, and all the examples were on European rivers. I was certain it [trash rakes] was the answer we were seeking for our Ohio River plant, so I followed up with the presenters, and they visited the plant and provided lots of information.

Still not convinced, I sent a team of engineers to Austria to view a few of the rakes in action. To make a long story short, we bought a rake. The rake paid for itself in two years. We eliminated the crane, the tractor trailer, and the landfill fees. As an aside, Duke Energy liked our rake so much that they bought one for their Ohio River plant, too.

Later, the AEP executives held a plant manager meeting at the Ohio River project, and they viewed the rake in operation. I never had to plead for permission to attend a hydro industry event after that.

POWERHOUSE: Do you have anything to say to prospective attendees of Clean Currents?

Jim Thrasher: I hope you have the opportunity to attend Clean Currents. I am certain you will gain information that you can use at your plants.

TO LEARN MORE

Thrasher’s experience is indicative of what you can look forward to at the upcoming Clean Currents event … plenty of access to education, advice, and guidance from waterpower industry professionals.

- View Program Schedule More than 80+ Sessions!

- See Who’s Exhibiting More than 150+ Exhibitors!

- See Who’s Speaking More than 160+ Speakers!

- Find Out Why Others Are Attending Take a Look!

To register for Clean Currents, click here.