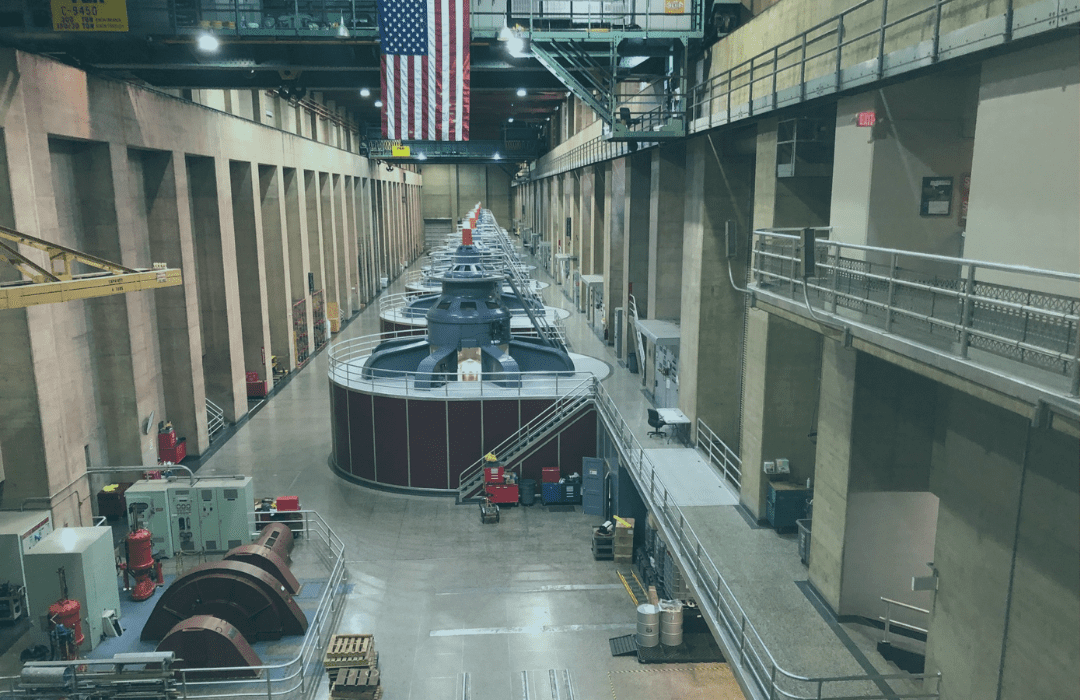

For hydropower facilities to operate, they require fluids and lubricants that facilitate turbine rotation to generate power. Most hydropower facilities use petroleum-based mineral oils—lubricants that, while inexpensive, can pose a threat to the environment if leaked from the facility.

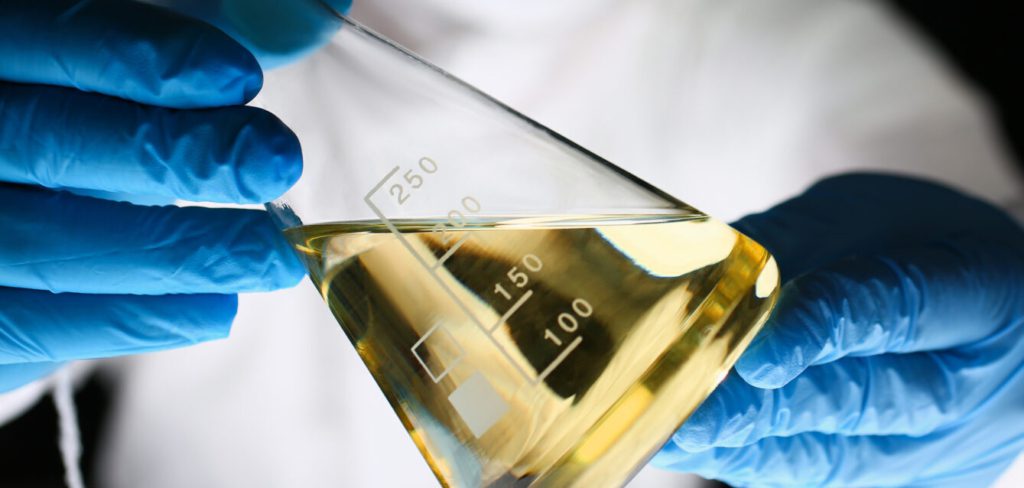

To address this concern, the Department of Energy’s Water Power Technologies Office (WPTO) is funding projects aimed at advancing research and development surrounding environmentally acceptable lubricants, known as EALs. The Environmental Protection Agency classifies an EAL as a lubricant (comprising two components: base oil and additives) that adheres to standards for aquatic toxicity, biodegradability, and bioaccumulation.

By replacing potentially harmful mineral oils with high-performing EALs, hydropower asset owners can generate clean electric power while supporting environmental sustainability.

WPTO is funding projects to develop, demonstrate, and validate EAL materials through a funding mechanism known as the Small Business Innovation Research (SBIR) program.

Through this program, WPTO is funding three industry-led projects, currently in their second phase of funding, that are advancing EALs toward commercialization.

Tetramer Developing Low-Pour-Point EAL

While working on a project for the National Science Foundation, Tetramer Technologies came across a molecule with a uniquely low pour point (-9 degrees C) that could be used as a foundation to create an environmentally acceptable lubricant. Low pour points allow lubricants to remain in a liquid state even at extremely cold temperatures. After securing WPTO SBIR funding, Tetramer spent Phase I of their efforts pressure-testing their molecule, successfully creating a lubricating fluid that met environmental regulations.

During Phase II of the project, Tetramer is focused primarily on two main goals: optimize and commercialize their newly developed fluid, the first of which concluded ahead of schedule. “With Phase II, we finished with the science aspect fairly quickly. Now our main focus is examining avenues to elevate this technology from a widget to a fully functional product with a tangible market,” said Zach Hunt, research scientist at Tetramer.

When asked about working with DOE SBIR funding, Hunt said he was impressed with the trust and freedom Tetramer was allotted for R&D. “We’ve really enjoyed working with DOE SBIR funding because they understand the timescapes for certain technologies, and allow time for proper R&D,” Hunt said.

Looking forward, Tetramer will continue engaging hydropower unit operators and existing lubricant vendors, to prepare their low-pour-point EAL technology for commercialization.

Rikarbon Upcycling Waste To Create BioLubes

Researchers at Rikarbon are using their SBIR funding to develop a 100% bio-based EAL, known as BioLubes, from upcycled waste materials. The bio-based lubricant poses multiple advantages for hydropower asset owners and stakeholders alike. “Our lubricant can substantially improve the overall health of hydropower production sites, while indirectly lowering carbon emissions,” described Basudeb Saha, founder and president of Rikarbon.

During Phase II, Rikarbon is collaborating with Pacific Northwest National Laboratory to develop BioLubes for hydropower applications. Rikarbon is also collaborating with a variety of hydropower turbine oil manufacturers and hydropower developers who currently produce and use mineral oil-based lubricants, working to ensure that hydropower facilities can seamlessly transition to BioLubes.

Thanks to SBIR funding, researchers at Rikarbon continue to make significant strides in their EAL research. “We were very fortunate to receive SBIR funding from DOE, which gave us the opportunity to explore this promising technology and bring BioLubes from paper to real life,” Saha added.

Polnox Preparing Environmentally-Friendly Additives and EALs

Many lubricants fail to qualify as EALs because of harmful additives which are added to base oils. Researchers at Polnox Corporation are working to develop clean additives that will facilitate increased use of EALs across the U.S. “It is essential that both components of a lubricant, the base oil and the additive(s), are developed with clean resources to ensure an effective EAL for the hydropower industry,” said Ashok Cholli, founder of Polnox Corporation.

Building on prior work with additives funded by the National Science Foundation, Polnox is utilizing DOE SBIR funding to further validate its proprietary technology. Phase II of their funding is centered around increased scaling and testing of their additives and EALs for commercial use at hydropower facilities.

Because Polnox had demonstrated a unique interest and the expertise to explore its idea further, the company were a perfect candidate for the SBIR program. “SBIR is an amazing tool for companies with ideas to develop novel technologies,” Cholli said.

Clean Lubricants for Clean Energy

The research funded by DOE aims to provide cost-effective products that convert more hydropower plants to using EALs to lubricate their machinery.

“It doesn’t make much sense to be producing clean hydroelectric power that requires the use of petroleum,” Cholli explained. Bringing EALs to the spotlight for hydropower project owners will be a significant step toward increasing the environmental sustainability of hydropower.

The research performed by these three projects will be instrumental in demonstrating the feasibility of using EALs in hydropower facilities, paving the way for easier regulation processes and a variety of environmental benefits.