American Municipal Power, Inc. (AMP) owns and operates some of the newest hydroelectric facilities in the U.S. today.

From this vantage point, the organization shares how it has achieved an outstanding worker safety record that continues to this day: no lost-time accidents since hiring the operating staff at any of AMP’s hydroelectric projects.

“AMP is proud of our employees working in hydro generation who demonstrate a high commitment to safety and support AMP’s mission and values,” said AMP COO Pamala Sullivan. “Their dedication is appreciated and helps contribute to the success of our members.”

In 2020, the Cannelton, Smithland, and Willow Island hydroelectric staff celebrated their five-year anniversary, with the Belleville staff marking 21 years of service. Between the 35 combined plant in-service years, well over 700,000 person-hours have been logged through April 2022 without a lost-time accident—a remarkable safety achievement given the diverse daily tasks at each project.

An AMP employee gives a safety briefing prior to racking a circuit breaker.

AMP was formed just over 50 years ago when a group of municipally owned electric systems joined forces to gain economies of scale in power supply, amplify their bargaining position, and fight for access to areas previously blocked by investor-owned utilities. AMP’s initial primary focus was joint ownership of electric facilities, pooled buying power in energy markets, and alternative means of generating, transmitting and distributing electric power and energy to benefit customer-owners.

AMP manages and supplies competitively priced, reliable wholesale power to member municipal electric systems. The organization also provides a forum for members to come together on mutual aid, safety training, other programs, and regulatory and policy matters. AMP provides these services on a cooperative, non-profit basis for the mutual benefit of all member communities. AMP services 134 members in nine states, including 133 municipals and one joint action agency.

TRIPLE CHALLENGE: THREE NEW PROJECTS IN 2016

AMP’s 42-MW Belleville Hydro Facility was commissioned in 1999, on behalf of 42 member communities participating in Ohio Municipal Electric Generation Agency Joint Venture 5.

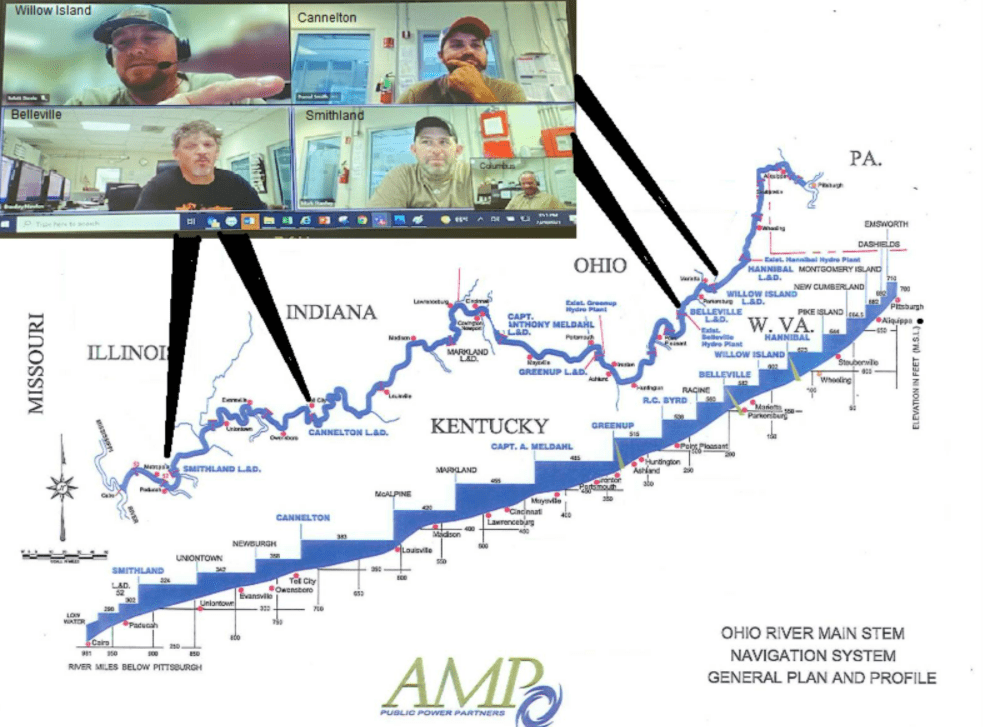

In 2016, AMP staff was tasked with simultaneously commissioning three new projects Cannelton, Smithland, and Willow Island developed on behalf of 79 member communities in Ohio, West Virginia, Virginia, Kentucky, and Michigan for a total of 206 MW.

All four run-of-the-river plants are located on the Ohio River, built at existing U.S. Army Corps of Engineers’ dams. Utilizing a combined total of 10 horizontal shaft bulb turbine-generators, the projects generate up to 248 MW of clean renewable energy. Connecting each plant output to the electric grid is a 138-kV or 161-kV transmission line ranging in distance, with 26.5 miles the longest.

Each plant is responsible for all plant operations, equipment maintenance, and transmission lines, as well as maintenance of the recreation sites for public use. “The hydro operators have to make good decisions each and every day while in the trenches in order to have accomplished such a safety record,” said William J. Sandell, AMP vice president of generation operations and development. “It only takes one mistake to endanger yourself or others and this record is a testament to their diligence and professionalism.”

SAFETY FIRST: HIRING A DEDICATED SAFETY DIRECTOR

During initial orientation for plant operators, AMP performed an assessment of the talent and capabilities of each plant operator at each facility to identify areas in which individuals could excel. Training courses were created for the new hires utilizing both the OEM manuals and training videos designed specifically for the operators. An operations and maintenance training manual was also developed, which included operating experiences on the Ohio River along with additional resources. The experienced Belleville operators were a key component in training the new hires for plant operations.

AMP hired a full-time corporate safety director in 2013 who was solely dedicated to AMP’s generating and corporate facilities. The safety director reviewed procedures and spent time in the plants to understand our maintenance and operating practices. The hydro supervisors embraced this effort and influenced the staff to do the same. Before the hiring process for the newer hydro plants in 2014, the corporate safety director reviewed the policies and procedures, which were a priority in the evaluation process.

AMP reviewed the safety programs at Belleville Hydro plant and improved the already successful practices before implementing at the new plants. Significant improvements were made in fall protection and in awareness. AMP capitalized on hiring experienced industrial workers with good attitudes toward safety.

Prior to commissioning each facility, AMP’s corporate safety director implemented new in-depth safety programs. The organization has maintained one set of safety rules whether in commissioning or operations. Contractors in charge of each construction site had specific safety rules that AMP also observed.

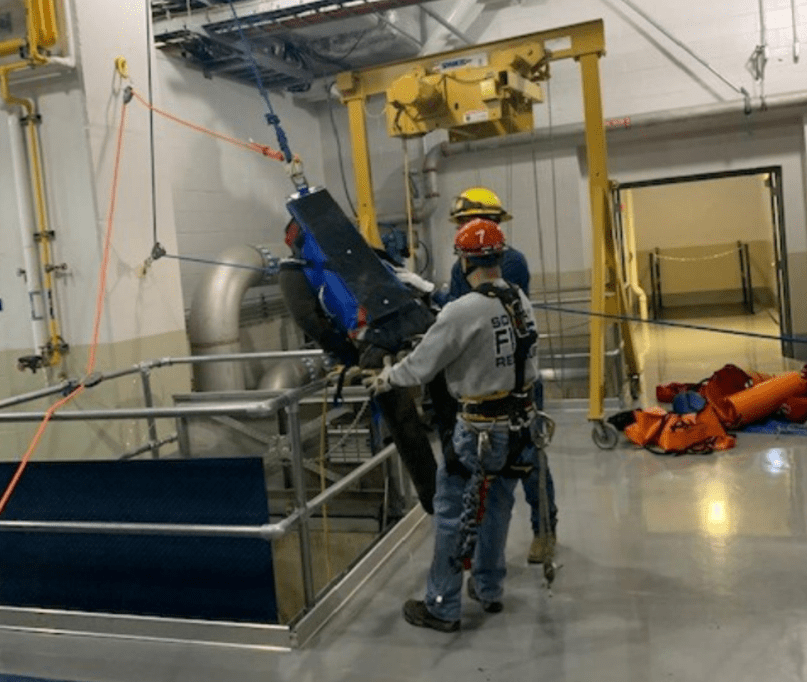

In this confined space rescue drill, a dummy was raised out of a 50-foot-deep pit in a basket.

Currently, John Kasanicky serves as AMP’s director of corporate health and safety. Kasanicky brings extensive power plant experience to the position. Hiring a dedicated corporate safety director definitely improved our focus.

SPECIFIC TACTICS TO ENSURE SAFETY

Specific tactics that AMP has undertaken include:

- Hiring practices include an evaluation of the candidate for safe practices and attitude.

- Near misses are recorded and discussed among the operating staff at each facility.

- The individual plants are under a centralized management and safety program.

- Fall protection improvements include the addition of a rolling tether drop line from the bridge crane for improvement of operator tie-off locations when working around the plant intake, edge of the operating deck, and open hatches that store the bulkheads.

- Each safety procedure is regularly reviewed and modified as needed. This includes Lock Out Tag Out, Confined Space, Fall Protection, Global Harmonized System, working alone and fork truck safety courses.

- Daily safety discussions among operators at each plant during shift change included high-risk jobs for the next shift.

- Operators are responsible for weekly topics and discussions with the other hydro sites, with this duty rotating between sites.

- Weekly tailgate topics are generated from the director of corporate health and safety. High-risk jobs for the week are reviewed between shifts with all of each plant’s staff.

AMP conducts and maintains weekly safety discussions between plants.

The plant operators’ collaboration and involvement has been a key program element. Each plant’s selected site safety officer coordinates safety activities with other operating staff, and AMP performs periodic safety audits of procedures and policies.

A REPOSITORY OF WORKER SAFETY LESSONS LEARNED

To address the critical importance of worker safety, the National Hydropower Association, of which AMP is a member, provides a repository of incidents and lessons learned regarding operations and maintenance of hydropower plants, including worker safety. This repository is in the form of the Operational Excellence (OpEx) voluntary event reporting system that receives, distributes, archives, and catalogs operating experiences and resulting best practices and lessons learned.

OpEx is the only hydro-specific event reporting program and database. The database contains more than 230 real-life events that have occurred at hydro plants throughout North America. The names of plants, plant owners, and personnel are redacted when the events are posted, in order to ensure confidentiality and security of all involved.

Access to the database is exclusively available to employees who work for NHA member organizations. For more details about the system, contact Luciana Ciocci at luciana@hydro.org.