With over 92,000 dams across the United States, the challenges, as well as the opportunities, owners and operators face are varied and complex.

National Hydropower Association’s (NHA) Clean Currents conference + tradeshow, which took place in Sacramento, California, this past October, featured eight sessions pertaining to dams, ranging from Federal Energy Regulatory Commission (FERC) led roundtable dialogue about the new Part 12 regulations to presentations about end-of-life decisions – dam removal and license surrender.

From these important exchanges, as well as by gleaning the big takeaways from NHA’s “Tips and Tools for Dam Safety Decision Making” webinar, three key topics emerged that are top-of-mind for dam owners today:

- Using risk assessments to make decisions about hazards and performance: With recent changes to FERC’s dam safety guidelines, dam owners and operators are adapting to the new comprehensive assessments, which will help develop deeper understanding of physical facilities and identify risk reduction opportunities. By understanding the extensive nature of the updated requirements, dam owners and operators will be able to navigate the process more confidently.

- Increasing use of 3-D modeling tools for visualization and communication: The rise of 3-D modeling tools has allowed engineers to feed a wealth of information into a model, which can act as a living representation of a dam while also serving as a repository of historical knowledge, enabling real-time safety assessments, helpful visualizations, and strategic communications.

- Decommissioning: With the Infrastructure Investment and Jobs Act providing $2.4 billion for dam safety, the act of retrofitting, rehabilitating, or removing dams has received historic funding. Asset owners pursuing a decommission can find success by assessing costs and environmental impacts – the more environmental impact studies included with the application, the easier the process.

Photograph of Shasta Dam in Northern California.

PERFORMING SEMI-QUANTITATIVE RISK ASSESSMENTS

Semi-quantitative risk assessments help to determine a project’s risk by incorporating data about hazards (such as floods and earthquakes), as well as other risks to dams, to better determine quantitative performance.

Daniel W. Osmun, senior professional associate at HDR, an NHA member organization, has had lots of experience with using semi-quantitative risk assessment (SQRA). He sees it as a useful tool for conducting comprehensive dam assessments and navigating changes in FERC’s licensing and re-licensing process.

Osmun explained that the semi-quantitative risk assessment enables dam operators to make a wide range of decisions, depending on whether the risk is tolerable, or if major investigations or analyses are warranted. He also emphasized the usefulness of the semi-quantitative risk assessment when modifying a dam, as it lays out which alternative option could or should be selected.

Engineers and climb team members with the U.S. Army Corps of Engineers Sacramento District, inspect the tainter gates at New Hogan Dam.

To understand more about the role of semi-quantitative risk assessment in dam safety, the recent history of FERC’s changes to dam safety guidelines must be discussed.

Prior to FERC’s recent changes to dam safety guidelines, dam owners, every five years, were required to retain an independent consultant to assess the dam’s structural, geotechnical, hydrologic, and operational safety; the process could be lengthy but was familiar to owners.

Beginning around 2003, the conversation about potential failure mode analysis gained traction, as owners tried to focus on determining what, potentially, could go wrong with a dam, including human error. In the pursuit of developing a deeper understanding of the physical processes and likely consequences of dam failures, the conversation about risk and severity of potential failures became more commonplace.

FERC’s approach, which, traditionally, had been standards-based, meant projects either met regulatory requirements or failed to do so. Although the standards for “factors of safety” were generally clear, some owners were frustrated that the process lacked a way to account for the relative risk associated with each failure mode and did not allow them to prioritize the factors they needed to address. At the time, federal dam-owning agencies, primarily the Bureau of Reclamation and U.S. Army Corps of Engineers, were developing more robust risk-based approaches.

Around 2012, FERC began an initiative to incorporate risk in its dam safety assessments, which included industry workshops, preparation of preliminary guidance documents, and several pilot projects across the country. Dam safety incidents, including the 2017 spillway failure at Oroville Dam in California and the 2020 failure of the Edenville Dam in Michigan, further focused attention on needed improvements to the dam safety inspection process at hydropower projects, ultimately leading to the 2022 issuance of revised FERC guidelines for independent consultant inspections.

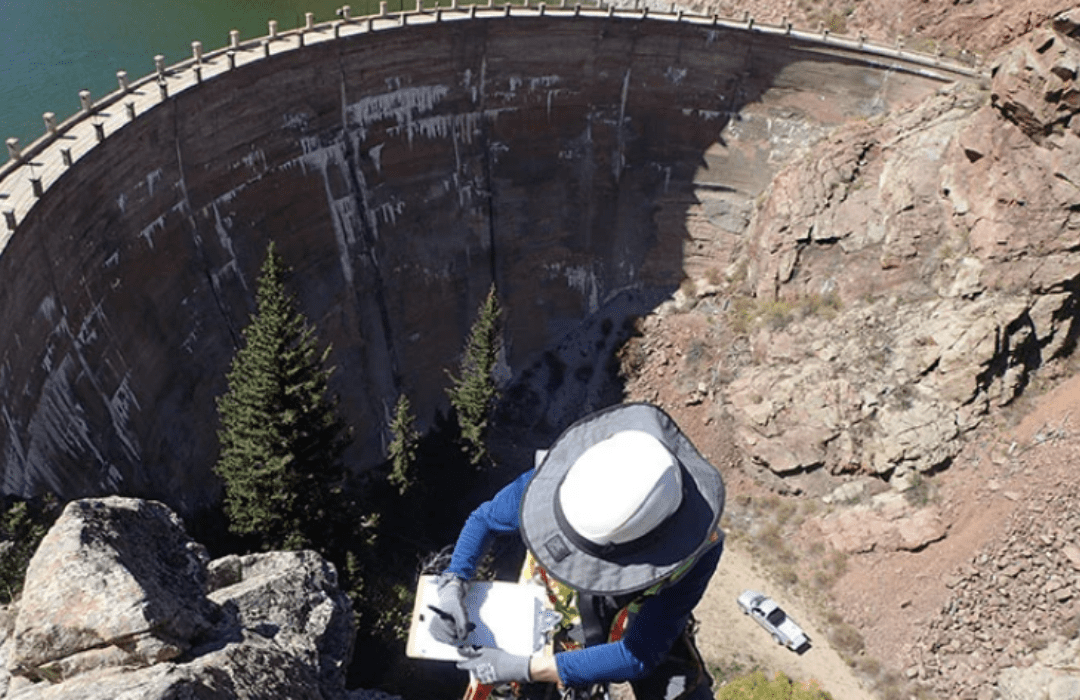

An engineer jots down notes while hanging from a cliff-face.

Part of the new requirements included a 10-year comprehensive assessment, which was designed to help owners take a deep, complete look at all aspects of the design, condition, and operation of the dam. Included in the comprehensive assessment was a semi quantitative risk assessment, which involved a process of gathering a team of dam consultants and subject matter experts to develop and document a collective opinion of the risks associated with the dam. This involved a new, in-depth potential failure modes analysis, including going back to historical documentation and photographs of the dam’s construction, examining whatever information was available. The team then produced an opinion of the risk associated with each failure mode, which was primarily dictated by two factors:

- The potential number of lives that could be lost in the event of a failure

- The probability of the failure occurring

As the semi quantitative risk assessment process began to emerge, some owners and consultants saw it as a highly prescriptive process complicated by a lack of industry experience, guidance, or direction in terms of how to best conduct these assessments successfully. With the process being both intensive and expensive, the outcomes from the assessment were not clear, and the owners of small hydro projects questioned how the process could be scaled to be practical for their projects.

In 2022, FERC notified certain licensees that one of their projects had been selected for the first round of comprehensive assessments, due to be completed in 2023. While there is optimism in the hydropower industry regarding the initiative, as the use of risk assessment is consistent with broader industry trends and provides several decision-making benefits, such as: developing a better understanding of the physical facilities, identification of risk reduction opportunities, and assisting in communicating about the importance of dam safety investments to top decision makers.

Photograph of an engineer for the U.S. Army Corps of Engineers participating in a dam inspection.

Additionally, there is discussion about the extensive nature of the requirements, as owners are submitting documentation about the comprehensive assessment plan and risk assessment team they’ll be using; FERC has rejected some of these plans a few reasons, including:

- The plan does not document adequate knowledge and experience on the comprehensive assessment team

- The time allowed for the line for completion is inadequate

The new requirements have also increased the demand for specific training, which has posed a challenge to FERC, as they’re not able to run courses directly, so they must work through other agencies to provide said courses. In addition, a facilitator is required to assist in the process, but the facilitator is required to have specific experience (in many cases with the United States Army Corps of Engineers or Bureau of Reclamation) but finding an approved facilitator can be a potential bottleneck.

3-D MODEL VISUAL TOOL APPLICATIONS

Technological innovation has impacted all industries, changing historical approaches to data collection and modeling, and hydropower is no exception. While the construction of dams began over 2,000 years ago, the past 25 years represents enormous growth for the hydropower industry in terms of the range and accessibility of tools designed to make dam safety assessment more efficient and intensive.

The first attempt to implement an automatic monitoring system began in the 1970’s, largely relegated to the transmission and display of data in staffed operation rooms. In the early 2000’s, the utility of limited AI tools emerged, but they posed a challenge in terms of referencing historical knowledge – information collected over the dam’s lifetime – as data storage technology was not expansive. Much of dam safety assessment relied on the experience of dam engineers, who accumulated critical skills throughout their careers, but faced the obstacle of knowledge transfer, as much of what they knew could not be easily passed along to new staff.

Engineers evaluate the stator core at Lochay Power Station.

While the industry made strides with surveillance tools – automatic data acquisition systems (sensors with remote monitoring), data transmission systems, and data processing systems (anomaly detection and monitoring) – throughout the early 2000’s, the automation aspect represented a major challenge, as technological limitations demanded a higher degree of human involvement.

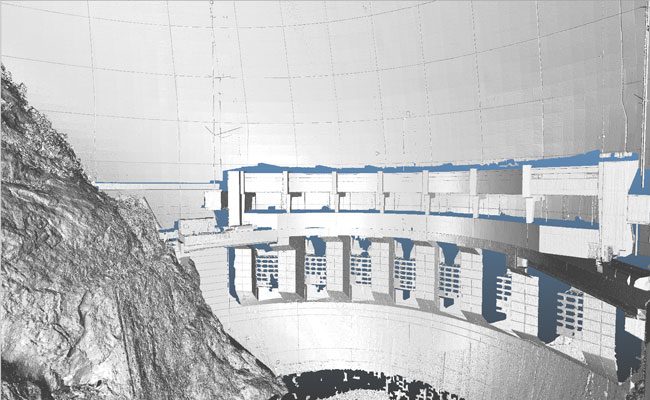

Currently, dam safety analysis innovation has enabled the use of robust 3-D modeling, which allows engineers to create instantaneous views of the problem under consideration. Through data collection and monitoring, engineers can develop a complete representation of a system’s state, which enables hypothetical analysis of dam performance. By feeding a 3-D model information from drawings, documents, instrumentation, geological mapping, and aerial photographs, engineers can build digital representations of projects, which can be analyzed in real-time to inform dam safety assessments.

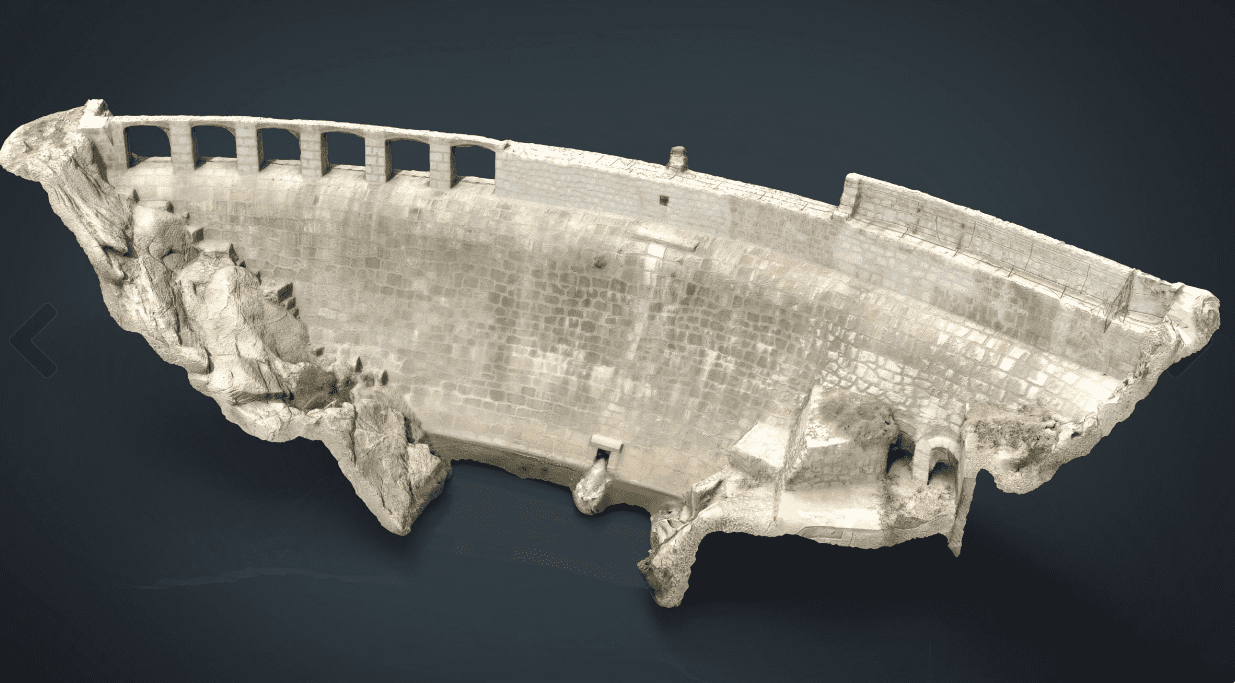

3-D rendering of a dam.

Tim Troung, chief dam safety engineer at the Yuba Water Agency, and Fred Snider, associate at Schnabel Engineering, shared tips on how 3-D modeling can serve as a useful tool for visualization and communication during dam safety projects.

In reference to dam safety assessments, Troung advised dam operators to “gather all the information, all the reports, all the drawings,” and “compile it into one single document.” He warned that this effort can be time consuming, but it yields voluminous information.

“Most people don’t realize that the free Adobe Acrobat Reader has been supporting 3-D modeling for about 15 years now. It allows me to tell a story about the dam foundation, and [it provides] a space to put all this different kind of information, storing it logically so that everything is at the same scale in [regards to its] relationship.”

The 3-D modelling process, Troung concluded, “is very valuable,” and Snider added, “We are continually working on updating it.”

Dam imaging created by collecting data using a combination of systems: high-resolution multibeam sonar, vessel-mounted LiDAR, and a high-resolution scanning bathymetric sonar

DECOMMISSIONING DECISIONS: WHAT TO CONSIDER

There is a developing trend in the United States to remove dams in instances where environmental, safety, and cultural benefits are deemed to ‘outweigh’ flood control, recreation, and irrigation. Regardless of where the decision to decommission originates from, the process is multi-faceted and costly.

Julia Scarpino Wood, founding partner of Rock Creek Energy Group in Washington, D.C., offered valuable advice on how to plan for and carry out a successful dam decommissioning project that adheres to FERC regulations.

Decommissioning, Wood said, is broadly defined as “shutting down power operations at a project, removing some or all parts of a project facility, restoring the site to pre-project conditions, and in rare instances [it] can involve dam removal.”

Floating platform aids in dam decommission.

Wood noted that decommissioning requires an initial license amendment or license surrender, emphasizing that there is “no process set forth in FERC regulations for decommissioning,” adding that a current legislative agenda pending on Capitol Hill could change that, thereby leading to “an improved process for FERC to address surrenders and decommissions.”

Since 1912, over 1,900 dams have been removed across the U.S., representing around 2% of the country’s 92,000 dams, with 57 removed in 2021. Currently, 15,600 dams are classified as ‘high hazard-potential structures,” meaning dam failure would result in loss of life and property damage, and 2,300 of the ‘high hazard’ dams have been labeled deficient, requiring immediate repairs.

Construction worker photographed removing the Sindi Dam in Estonia

With rehabilitation of high-hazard dams estimated to cost over $20 billion, The Infrastructure Investment and Jobs Act, which included $2.4 billion for dam safety, and passed in 2021, addresses ‘problematic’ dams in three major ways:

- Retrofitting dams to enhance electricity production

- Rehabilitating dams to ensure safety and efficiency

- Removing dams that offer little benefit while harming the environment

“Decommissioning is a lengthy process,” Wood said, and it can be aided by “planning and anticipating stakeholder interests early on. By anticipating the length of time it’s going to take to shop your proposals before agencies and interested parties get their feedback.”

To ensure success with decommissioning, Wood urged dam operators, “Assess your costs and environmental impacts. [It’s] crucial to understand what you’ll be getting into, and the more environmental assessments you can include with your application before work begins, the easier and smoother the process will be.”