Sponsored Content

Reliance on traditional methods and tools creates cost and other barriers that have long stymied low head hydropower development at existing facilities. A new modular powerhouse, however, gives developers and owners the key they’ve needed to unlock its significant potential.

Modular Powerhouse – a Viable Solution

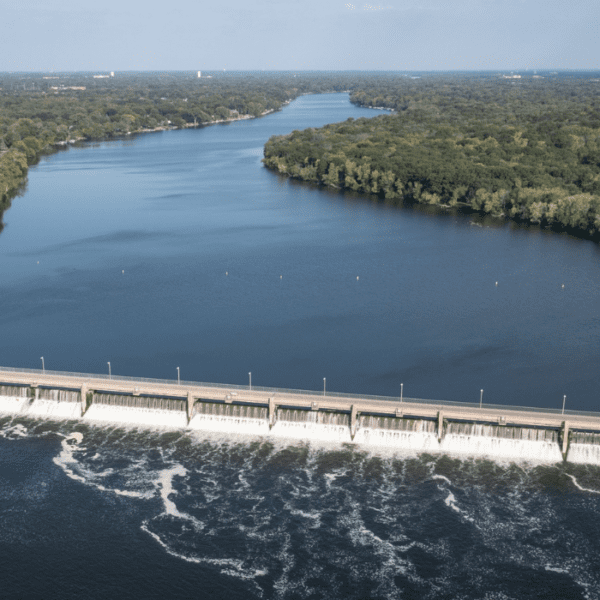

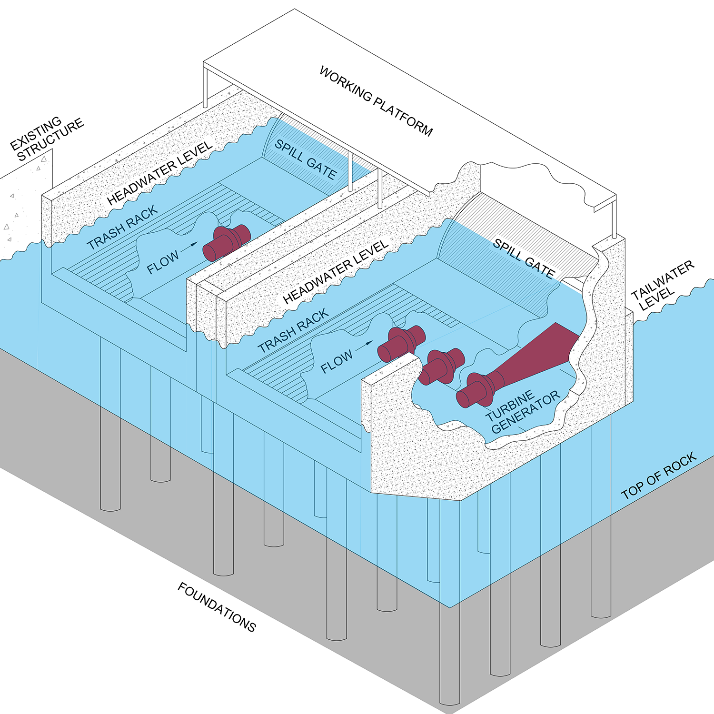

Figure 1 Rendering of an installed modular powerhouse

High capital investment, excavation and construction costs — coupled with total installation time — significantly impact the feasibility of traditional hydropower generation on undeveloped stream reaches and low head greenfield sites. The modular powerhouse, however, bypasses those barriers. It is a streamlined and efficient approach to adding electric power generation to existing facilities that have untapped potential for generation. By maximizing offsite construction and minimizing field assembly, eliminating temporary infrastructure such as cofferdams, and employing existing technologies available on the market, the modular powerhouse offers new ways to harness clean, sustainable, and renewable energy. The scalable solution may reduce design and construction costs.

This approach is well-suited to adding electric power generation to existing facilities that currently do not generate or have untapped potential for generation. This includes unused locks, flood control gated structures, downstream or upstream of a low head dam.

How Does the Modular Powerhouse Work?

The modular powerhouse consists of standard-sized modules that may be constructed off-site or adjacent to the site. The modules can then be transported to the site by shipping or floating for installation on a prepared foundation.

Since the modules may be produced off-site, they can be produced as a standard unit that may be broadly applied and installed at multiple sites. Furthermore, multiple modular hydropower units may be combined at an individual site to increase power output for a given head and flow.

How Can the Industry Make Low Head Sites Feasible?

Scalability Consideration

Production of a standard unit allows for broader application and installation at multiple sites. Multiple modular hydropower units enhance the scalability factor because they can be combined at an individual site to increase power output for a given head and flow. For instance, a given site may contain four modular powerhouses with three turbine- generator units each for a total of 12 turbin- generator units installed at the site.

Off-site Construction

The off-site production of the modules allows for flexibility in construction techniques and timing, material specifications, and use of existing infrastructure at a facility, such as cranes, forklifts, or personnel facilities. This increases the amount of construction in a controlled environment and minimizes field construction, reducing the on-site construction time from years to months. Additionally, delays due to high water levels at the project site are greatly diminished.

Use of Existing Technologies

Turbine-generator suppliers have spent years developing equipment suitable for low head sites. By using these existing technologies, we can take advantage of the current research and development that is readily available without adding the expense of reinventing the wheel.

Unique Foundation Approaches

Cofferdams and excavation are a large cost in constructing a conventional hydro plant. The modular powerhouse can potentially anchor in an existing rock surface, piles, or other suitable foundations that may provide a level surface for the module to rest and restrain the module against hydraulic and buoyancy forces. Flexibility of foundation types may eliminate the need for a cofferdam to dewater the area.

Desired Results

A modular hydropower system has numerous advantages over a traditional hydropower development making it particularly attractive in low head site development. Locating the modules in a spillway bay without requiring significant modifications to the existing dam and spillway reduces impacts to dam safety. The off-site, standardized modular construction also minimalizes environmental impacts due to construction at existing non-power dams. The result: economically sound and environmentally responsible investment in clean, renewable, sustainable energy.

To find out more about Black & Veatch’s patented approach Modular Hydropower, please visit: https://www.bv.com/resources/modular-hydropower-system