Sponsored Content

During any turbine and generator rehabilitation project, the hydro project owner needs extensive support with its rotating machinery including: initial condition assessments; fitness-for-service evaluations; specification developments; support to rewinding, rehabilitation, and automation; and uprate studies for turbines, generators, and balance of plant equipment.

The more precise the data given to the owner, the more valuable the support.

Challenges in Hydro Units Rehabilitation

As hydro units age and approach the end of service life, longer and more extensive rehabilitation projects often need critical attention. It is imperative that the owner does not underestimate the importance of pre-outage planning and preparation.

In-depth studies and analyses not only help determine the initial scope of work, but they can also often reduce overall rehabilitation time and expense on projects.

A well-developed plan, accompanied with lessons learned, is also invaluable for future rehab work on sister units.

The goal of the initial assessment is to ensure that the rehabilitation project will be optimally casted, fitted, and customized in a way that mitigates risk and minimizes surprises, thereby reducing change orders.

With reliability and process predictability as a goal, engineering studies must consider all the real aspects and conditions of the units, research potential problems, assess the present condition, and determine remaining design margins and service life.

If done correctly, these studies result in the most cost-effective approach and plan for the rehabilitation project, while also keeping in mind that sometimes replacement for aging components is more efficient than repair. The more precise the study, the better prepared the owner is when moving forward.

Electromagnetic Fitness-for-Service

In recent years, owners have seen that generator studies need to include not only the traditional analytical approach but also a full electromagnetic finite element analysis (FEA) study.

ANSYS Electronics Desktop package is a valuable tool that allows for electromagnetic fitness-for-service studies. From RMxprt analytical calculations on the main machine performance parameters to detailed electromagnetic FEA calculations with the tool Maxwell, owners can confidently determine the most cost-effective approach with design analysis and uprate studies in varying transient and magnetostatic simulations.

The analytical tool RMxprt is the starting point when designing and evaluating a rotating electrical machine parameter. Fast and reliable, it can deliver inductances, reactances, time constants, main components weight, forces, slot build up, short circuit levels, excitation levels, losses, efficiencies, resistances, and winding arrangements.

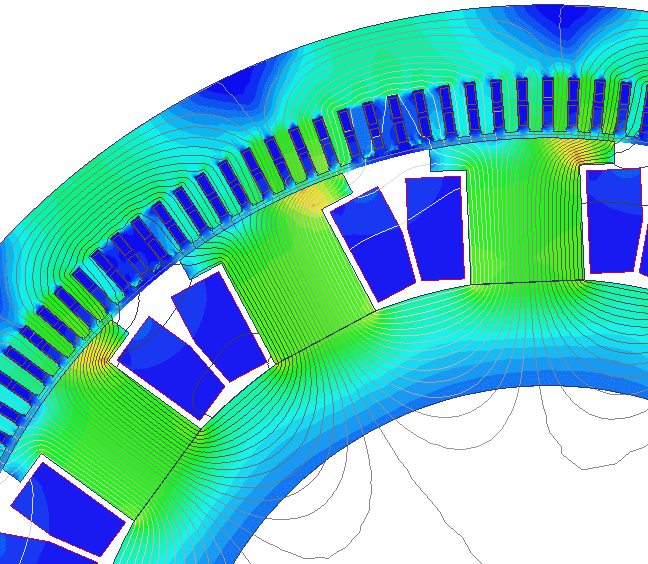

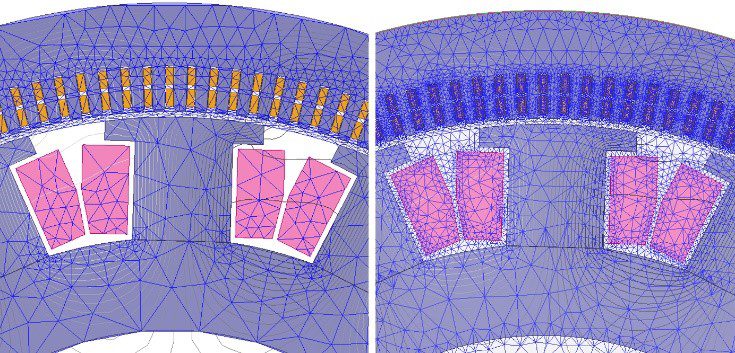

The FEA tool Maxwell imports the complete machine geometry from RMxprt and then provides electromagnetic design performance optimizations. These optimizations include higher output power, less total losses and improved efficiencies, magnetic pull, and local flux saturation, which results in significant refinement of the previously obtained analytical parameters.

The electromagnetic simulations results provide the basis for a series of mechanical calculations that result in a more precise parameter estimation. This precise estimation is paramount for a proper machine design and later operation in the field.

In the example in the graphic below, by having a more refined meshing operation, the rotor’s unbalanced magnetic pull increased by 3.2%. With the improved number, Black & Veatch’s rotor dynamic analysis delivered a more robust and reliable mechanical report, and subsequently created greater value for the owner.

Black & Veatch consistently supports hydro generator owners with electromagnetic fitness-for-service studies along with generator components specifications, technical and economic evaluation proposals, vendors’ documents, and drawings review.